Discover the Digital Dominance of Field Service Management Software for Manufacturing

Manufacturing businesses today function in a highly dynamic and rapidly changing environment. As manufacturers work to differentiate themselves through products and services, the most progressive companies are making advances to deploy technology in field service management for manufacturing. These manufacturers are empowering their technicians with the right kind of information so that they fix issues at the first visit and also prevent it from happening by identifying and addressing these problems from the get-go.

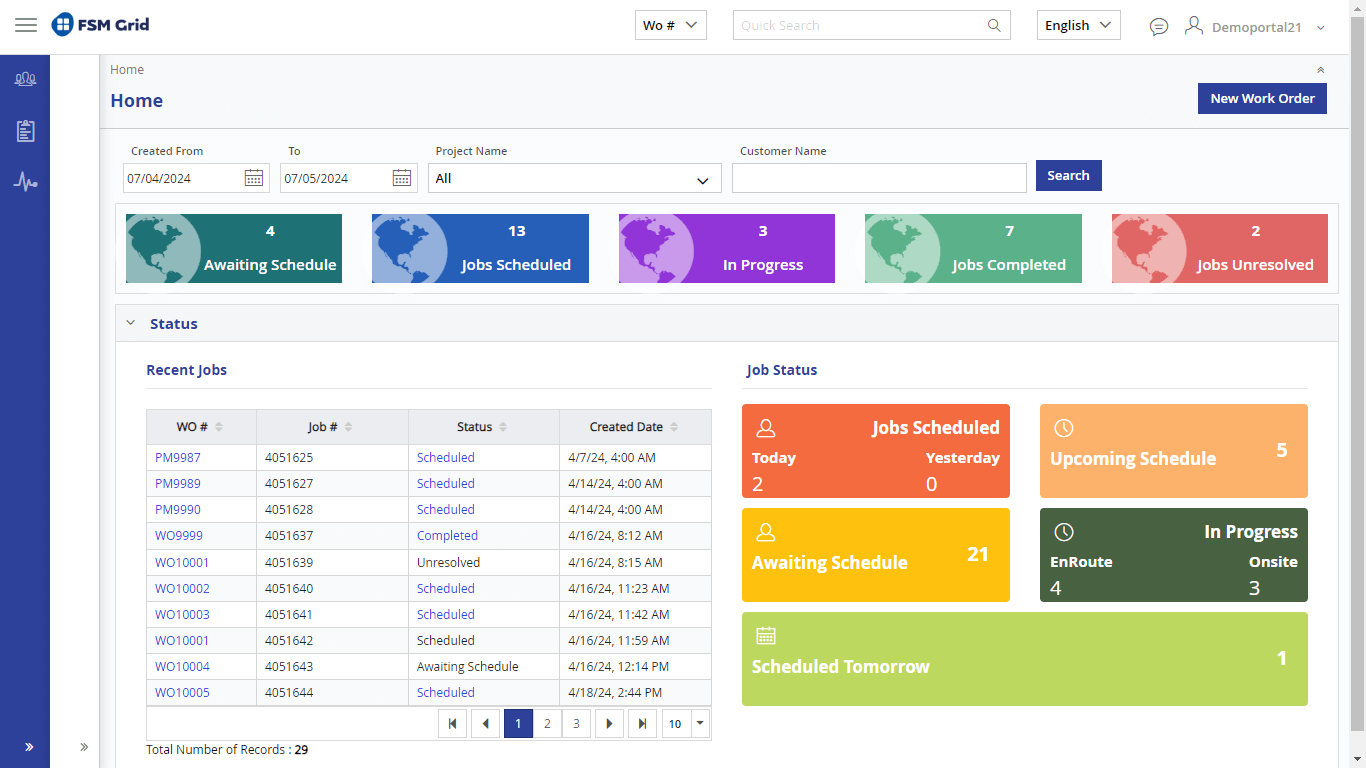

To ensure customer satisfaction and improve business efficiency, manufacturing organizations must connect with the appropriate technology that may help them anticipate consumers’ requirements and respond ahead of the competition. By leveraging FSM Grid, these manufacturing companies producing heavy machinery, industrial appliances, construction equipment, and the like can operate more efficiently and have better chances of improving their bottom line. With our SaaS-based manufacturing work order software, businesses can also streamline process flow, manage contractors and inventories, lower the risk of breakdowns and downtimes, and ultimately reduce costs.

Automate Scheduling and Optimization

Automate Scheduling and Optimization

Optimizes Inventory

Optimizes Inventory

Manages Contractors

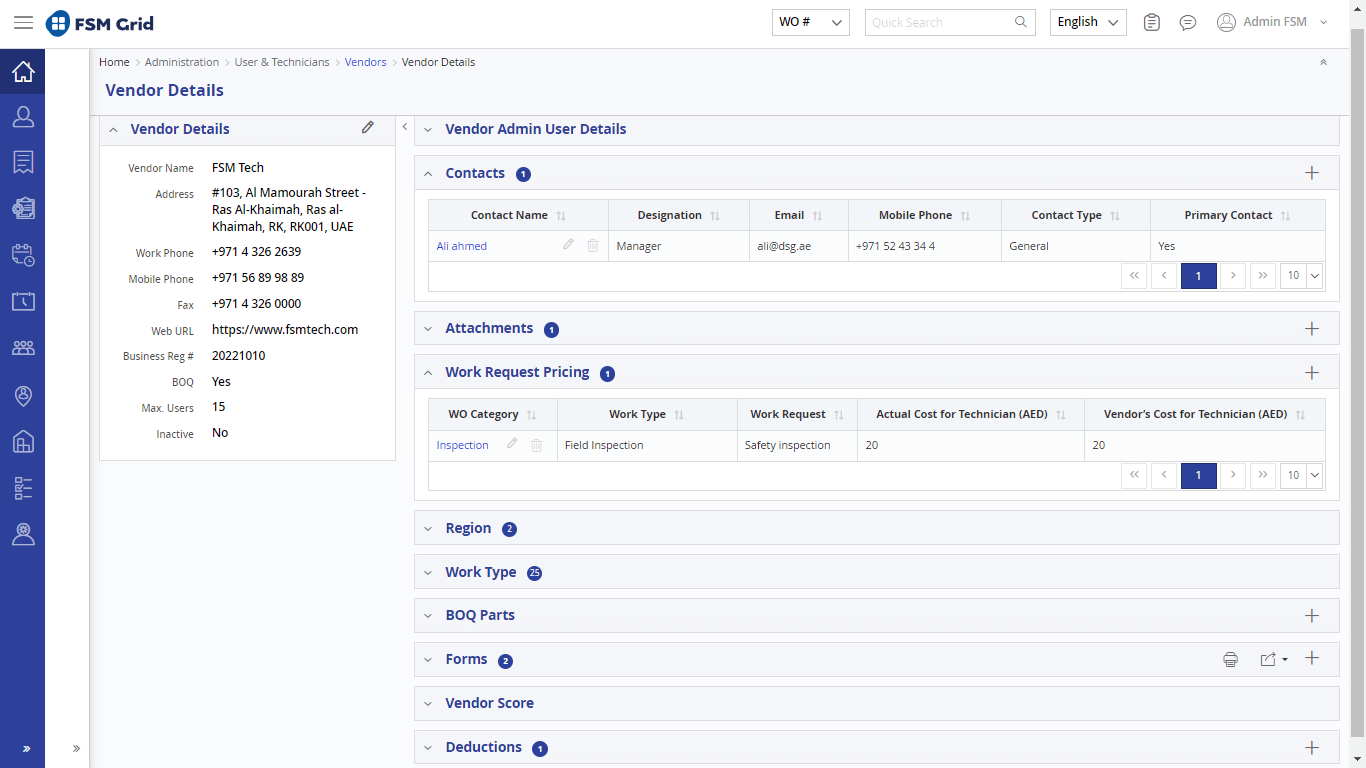

Businesses need to ensure that their contracted service partners stay updated on work orders, entitlements, documentation, services, and equipment histories. FSM Grid goes beyond communication and tracking technicians. It empowers the company to manage their entire field service network, including contractors and subcontractors, in real-time. This robust manufacturing business management software provides access to a vendor/contractor portal. Vendor users can access visibility services, assign work orders, schedule jobs for their technicians, keep track of and update status in real time, and approve jobs.

Proactive Maintenance

Proactive Maintenance

Insightful Reports and Tracks KPIs

Insightful Reports and Tracks KPIs

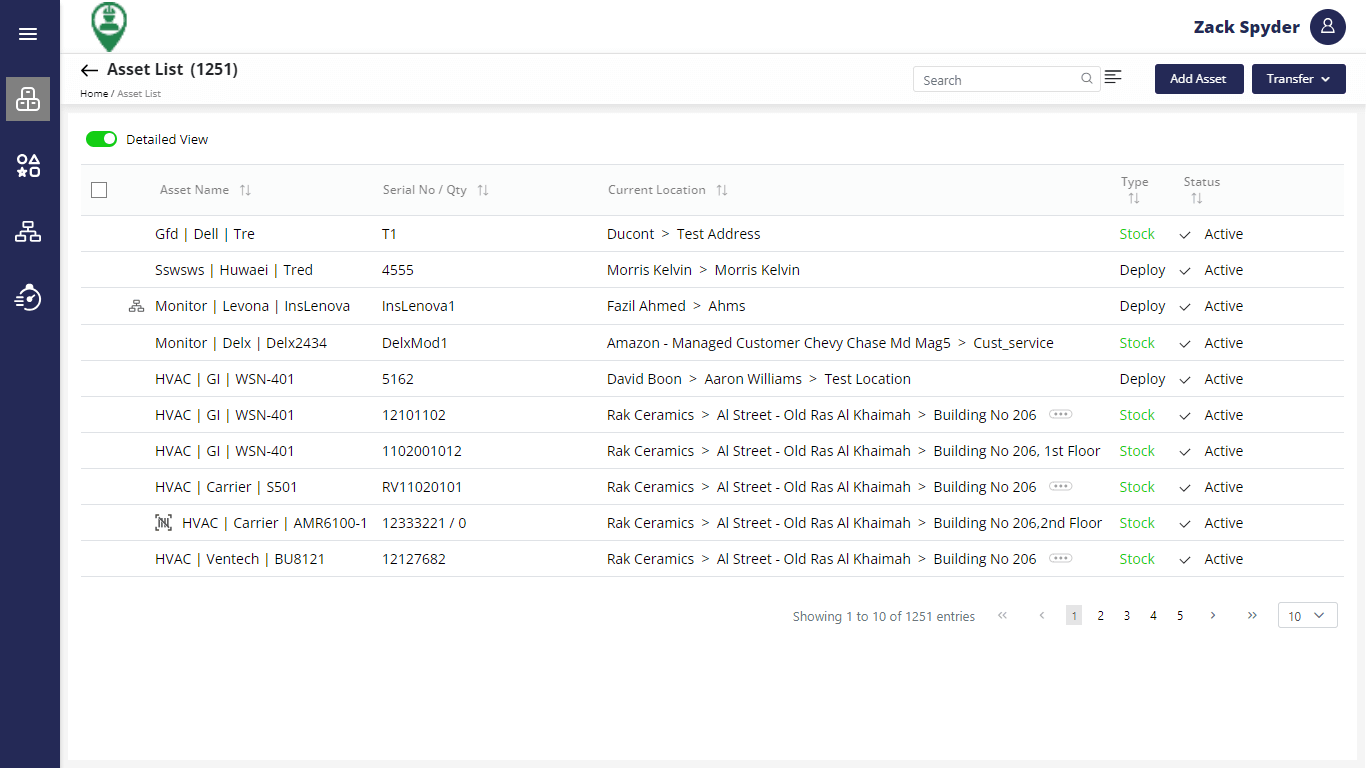

Manages Assets

Field service manufacturing work order software has inbuilt asset management features, using which the in-depth details of the asset, including the various asset attributes and the asset’s Bill of Materials, including the schematic mapping of various components, can be maintained. Our asset management module in FSM Grid helps technicians access important information about an asset’s maintenance history, bills, client’s site location, serial numbers, and attributes.

Parts Management

Missing parts are one of the biggest reasons for returns, negatively affecting both your asset service time and the customer’s experience. To avoid such outcomes, you need to get robust parts management software. While it is standard for manufacturing organizations to provide the right parts to technicians in the field, it is equally important to manage reverse and depot repair processes without understocking or overstocking your inventory. With FSM Grid, you can automate your return processes and achieve your fixed goals.

Built-In Self-Service Portal

FSM Grid high-tech/high-touch software allows your customers to create and self-schedule jobs based on their time frames and requirements. This field service software for manufacturing outperforms all other in-field service management technologies in enhancing customer satisfaction.